Worm Gear Design Calculation Pdf

ZAR3+ generates true-scale drawing of worm and worm gear. ZAR3+ provides an additional input window for modifications of tooth height factors and profile shift coefficient x. These functions are useful for design of complementary gears of steel worm and plastic worm gear. ZAR3+ calculates tooth thickness and over pin/ball diameters (OPD).

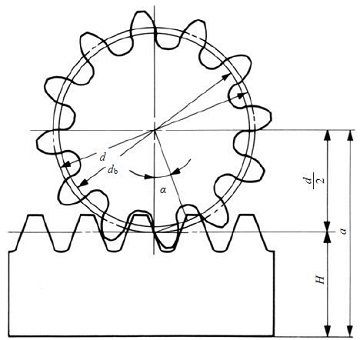

A worm gear box must contain a worm and a mating gear (helical gear) and normally the axis of the worm is perpendicular to the axis of the gear. Look at the picture below:

Where,

Calculations for worm gears are the same as for. Worm Gearing 50 Lead Angle Worm threads are. Perature and the details of the gear mesh design. Worm gear.pdf - Free download as PDF File (.pdf), Text File (.txt) or read. Of a worm gear is related to its circular pitch and number of teeth Z by the formula.

D1 – Pitch Diameter of Worm

- Formulas for gear calculation. To design a gear tooth profile which rolls through the mesh without friction. Formulas for gear calculation - external gears. Download Free Lecture Notes-Pdf Link-IX. A box must contain a worm and a mating gear (helical gear) and normally the axis of the worm is perpendicular to the axis of the gear.

- Worm gear correction x Worm size can be specified using the: worm diameter factor q helix direction γ pitch diameter d 1 Auxiliary Geometric Calculations Design. Worm Gears: Technical Information Characteristics The simplest way to obtain a large speed reduction with high torque in a compact space is with worm gear drives. KHK stock worms.

- All of these calculations are based on the application of envelope theory and analytical. They are made by breaking down the worm gear couple into a succession ot elementary rack-and-pinion gears, having variable profiles determined in planes parallel to the midplane of the gear. 1shows the operating geometry of a worm.

D2 – Pitch Diameter of Gear

C – Centre to Centre Distance between the Worm and the Gear

This worm gear design tutorial will discuss up to the selection of the module and pitch and the calculation of the number of teeth, pitch circle diameter and centre to centre distance between the worm and gear. We will use the AGMA formulae for doing the calculations. Design calculations of the other aspects of the worm gear will be discussed in a subsequent part of the tutorial.

Steps of the Design Calculation

- The axial pitch of the worm and the circular pitch of the gear must be same for a mating worm and gear. We will use the term Pitch (P) for both the pitch in this tutorial.

- Also, the module of the worm as well as the gear must be equal for a mating worm and gear.

- Now, let’s say we have the following design input:

Speed of the Worm (N1) = 20 RPM

Speed of the Gear (N2) = 4 RPM

- And, we have to find out the Module (m), Pitch (P), Number of helix of Worm (T1), Number of teeth of Gear (T2), Pitch circle diameter of Worm (D1), Pitch circle diameter of Gear (D2), Centre to centre distance(C).

- Select the suitable module and its corresponding pitch from the following AGMA specified table:

Module m (in MM) – Pitch P (in MM)

2 ————————-6.238

Worm Gear Calculation

2.5 ———————- 7.854

3.15 ——————— 9.896

4 ————————- 12.566

5 ————————- 15.708

6.3 ———————– 19.792

8 ————————– 25.133

10 ————————- 31.416

12.5 ———————– 39.27

16 ————————– 50.625

20 ————————– 62.832

- Say, we are going ahead with the Module as 2 and the Pitch as 6.238.

- Use the following gear design equation:

N1/N2 = T2/T1

And, we will get:

T2 = 5 * T1……………….Eqn.1

- Now use the following AGMA empirical formula:

T1 + T2 > 40………………Eqn.2

- By using the two equations (Eqn.1 & Eqn.2), we will get the approximate values of

T1 = 7 andT2 = 35

- Calculate the pitch circle diameter of the worm (D1) by using the below AGMA empirical formula:

D1 = 2.4 P + 1.1

= 16.0712 mm

- The following AGMA empirical formula to be used for calculating the pitch circle diameter of the gear (D2):

D2 = T2*P/3.14

= 69.53185 mm

- Now, we can calculate the centre to centre distance (C) by the following equation:

C = (D1 + D2)/2

= 42.80152 mm

- The below empirical formula is the cross check for the correctness of the whole design calculation:

(C^0.875)/2 <= D1 <= (C^0.875)/1.07

Observe that our D1 value is falling in the range.

Conclusion

The worm gear box design calculation explained here uses the AGMA empirical formulas. A few worm gear design calculator are available on web, and some of them are free as well.

In the next worm gear box design calculation tutorial we will discuss the force analysis of a worm gear box.

Related Reading

Helical Gear vs. Spur Gear: If you have observed a spur gear application, you may have noticed that spur gear can be replaced by helical gear. Where should a helical gear should be used? What are the benefits and disadvantages of doing so?

Input Parameters

Teeth type - common or spiral

Gear ratio and tooth numbers

Pressure angle (the angle of tool profile) α

How to run bully scholarship edition in windowed mode. Then I downloaded one of the best mods called 'Super Mod', and it was still running normally. Only thing I can hope for is Bully 2 or Bully remake in the future. Well, just some pirace games of Bully works for Windows 10, but Rockstar make this game to Rest in Peace. At first crashes but then the game was normal. But now the game crashes frequently.

Module m (With ANSI - English units, enter tooth pitch p = π m)

Unit addendum ha*

Unit clearance c*

Unit dedendum fillet rf*

Face widths b1, b2

Unit worm gear correction x

Worm size can be specified using the:

- worm diameter factor q

- helix direction γ

- pitch diameter d1

Auxiliary Geometric Calculations

Calculated parameters

Common gearing ZN

Axial module

mn = m | |

Normal module | mx = mn cos γ |

Axial pressure angle | αx = a |

Normal pressure angle | αn = arctg (tg α cos γ) |

Helix/lead angle | γ = arcsin z1/q |

Spiral gearing ZA

Axial module

mn = mx / cos γ | |

Normal module | mx = m |

Axial pressure angle | αn = arctg (tg α cos γ) |

Normal pressure angle | αx = α |

Helix/lead angle | γ = arctan z1/q The configuration details for this step can be found in the installation guide. |

Worm Gear Design Calculation Pdf Download

Normal tooth pitch

Axial tooth pitch

px = πx

Basic tooth pitch

Lead

pz = z1 px

Virtual/alternate number of teeth

Helix angle at basic cylinder

sin γb = sin γ cos αn

Worm pitch cylinder diameter

Worm gear pitch circle diameter

d2 = z2 mx

Worm outside cylinder diameter

Worm gear outside circle diameter

da2 = d2 + 2m (ha* + x)

This is a quick 'how to' guide to make a bootable Windows 10 USB drive/stick on a Mac from an ISO file. If you haven't already done so, you'll need to download the Windows 10 disk image (ISO) file from Microsoft. The process is straightforward, but requires one third party tool called wimlib and some terminal/command prompt usage. Create Bootable USB for Mac on Windows 10, Mac and Windows file system is completely different, so you are not able to create bootable USB for Mac with PowerShell, CMD or Rufus.If you remembered, till MacOS sierra the Apple file system was Hackintosh, but MacOS 10.13 High Sierra has the technology of Apple Filesystem. That’s why we can’t create bootable USB with Windows tools. How to Create a Bootable Mac OS Installer from Windows Windows is not directly compatible with the HFS+ disk image formats used by macOS. You'll need to install Ubuntu Linux in VirtualBox to create the macOS recovery disc. Install VirtualBox v6.1.4 (not v6.0). Bootable windows image for usb mac. Download the Windows 10 ISO file. You can download the ISO file straight from Windows. Download Windows ISO file. Go to the Microsoft official website and download the free ISO file for.

Worm root cylinder diameter

Worm gear root circle diameter

df2 = d2 - 2m (ha* + c* - x)

Worm rolling(work) circle diameter

Worm gear rolling(work) circle diameter

dw2 = d2

Worm gear root circle diameter

Center distance

Chamfer angle of worm gear rim

Worm tooth thickness in normal plane

Worm gear tooth thickness in normal plane

Worm tooth thickness in axis plane

sx1 = s1 / cos γ

Worm gear tooth thickness in axis plane

Work face width

bw = min (b1, b2)

Contact ratio

Worm Gear Design Formula

εγ = εα + εβ

where:

Minimum worm gear tooth correction

Worm Gear Design Pdf

where:

ha*0 = ha* + c* - rf* (1 - sin α)

c = 0.3 | for α = 20 degrees |

c = 0.2 | for α = 15 degrees |